GAP Harmonization Initiative

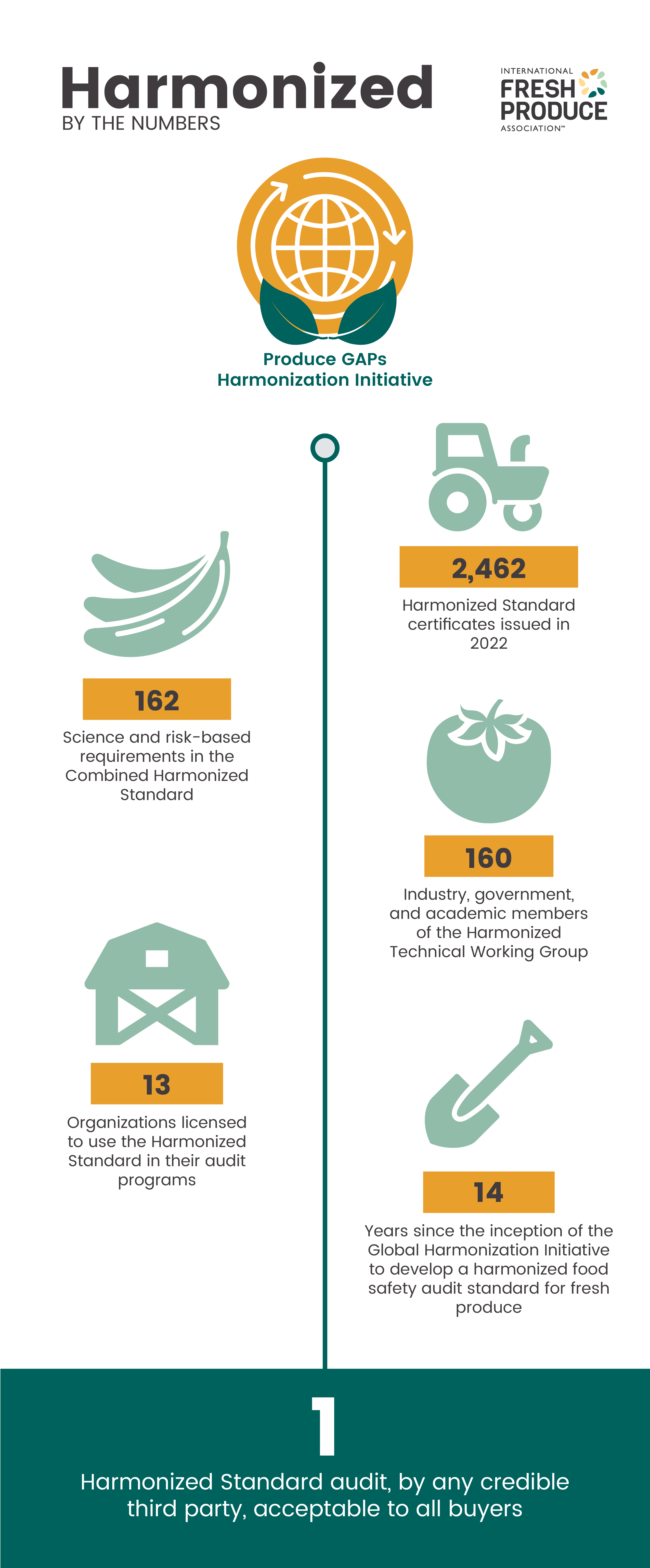

In June 2009, the former United Fresh Food Safety Council endorsed a plan to drive harmonization of GAP standards, to reduce audit fatigue and allow operations to focus their food safety resources on achieving food safety, rather than passing audits. This plan evolved into the Produce GAP Harmonization Initiative, an all-industry effort including growers, shippers, produce buyers, government agencies, audit organizations and other stakeholders.

The goal of the harmonized standard is “One audit by any credible third party, acceptable to all buyers.” To achieve this goal, the Initiative developed food safety Good Agricultural Practices standards and audit checklists for pre-harvest and post-harvest operations, applicable to all fresh produce commodities, all sizes of on-farm operations and all regions in the U.S., and has made them available for use by any operation or audit organization at no cost.

Produce GAPs Harmonized Standard Auditor Training

Please reach out to Tressie Jefferson for future training dates.

The Harmonized Standard Auditor Training will feature the official training materials developed by the Harmonized Standard Calibration Committee, designed to standardize food safety auditors’ use and expectations of the Harmonized Standard.

This training is open to all audit organization members, growers, packers, and other interested parties currently using the Harmonized Standards. Over the course of four half days online, the training will cover the details of what an auditor should expect to see at an operation, how an auditor evaluates an operation based on the evidence they observe, and how evaluations may change based on different scenarios.

Spaces are limited, so sign up quickly when courses are added.

Cost Member: $495/ Non-Member $695

Produce GAPs Harmonized Audit Standard – Version 2.0

Effective until April 30, 2024

On July 12, 2023, a public meeting and Q&A session was held to discuss the latest version of the Produce GAPs Harmonized Standard (Version 3.0). During the meeting a brief background and history of the standard was provided, as well as a high level overview of the changes made between Version 2.0 and Version 3.0.

Combined Harmonized Standard V.2.0

Download

Combined Harmonized Standard V.2.0 (Spanish)

Field Operations and Harvesting Harmonized Standard V.2.0

Post-Harvest Operations Harmonized Standard V.2.0

Produce GAPs Harmonized Audit Standard – Version 3.0

Implementation date May 1, 2024

Revision Cycle History and Important Dates

Every three years, the Produce GAPs Harmonized Standard goes through a revision process in collaboration with the Technical Working Group and Calibration Committee. The first version of the standard was released in 2011, followed by updates to incorporate the FSMA Produce Safety Rule requirements in 2014. The first official revision cycle began in September 2019 and Version 2.0 was published in April 2020. The most recent revision cycle began in August 2022 and Version 3.0 was published May 2023. Certification bodies will have one year after the new version publishes to transition fully to Version 3.0 (May 2024).

The next revision cycle will commence in late 2025 with Version 4.0 due to publish in the spring of 2026. Interim changes may be proposed, as identified by the Technical Working Group and Calibration Committee according to industry feedback and final regulations published (e.g., FSMA Produce Safety Rule agricultural water requirements).

Download the Produce GAPs Harmonized Standard:

Harmonized Standard Version 3.0

Harmonized Standard Version 3.0 - Redline (markup changes from Version 2.0)

Initiated in 2009, a diverse group of 150 industry stakeholders and technical experts reviewed 13 commonly accepted GAP audit standards, with the goal of developing “One audit by any credible third party, acceptable to all buyers.” In doing so, the steering committee aimed to help reduce audit fatigue and allow operations to focus their food safety resources on achieving food safety, rather than passing duplicative audits. The Produce GAPs Harmonized Standard was officially published in 2011. IFPA (formerly United Fresh) has remained the secretariat for the standard since that time.

Since then, the Harmonized Standard:

- Has been aligned with the Produce Safety Rule, as recognized by FDA

- Has been popular among smaller growers due to its focus and flexible, risk-based requirements

- Has been accepted by a host of large buyers

- Is available through 12 organizations licensed through IFPA (formerly United Fresh)

- Is available as a GFSI fully-benchmarked standard through GLOBALG.A.P.’s HPSS program, and as a GFSI recognized technically equivalent standard through the USDA-AMS HGAP+ program

What kind of Harmonized Standard certificates are available? What are the differences?

IFPA licenses the Harmonized Standard to auditing organizations.

All licensees for the Harmonized are required to use the same technical standard verbatim, with no changes in wording permitted. However, additional items may be included in the audit, such as those required for GFSI benchmarking, provided that those items are clearly marked. Licensees may have different audit structures, scoring, and certificates, as these operational characteristics are not governed by IFPA. Licensees remain harmonized through mandatory participation on the Calibration Committee, meeting quarterly to discuss questions on interpretation and other relevant updates regarding the Harmonized Standard.

Many licensees offer audits against the Harmonized baseline technical standard, appealing to those who do not require GFSI-recognized 3rd party audit certificates. Other licensees offer GFSI-recognized Harmonized Standard audit certificates. Some offer both! Licensees offer different types of certificates using the Harmonized Standard to meet customer needs:

- 3rd Party , not GFSI recognized

- 3rd Party, GFSI technical equivalence

- 3rd Party, GFSI recognized

GFSI Recognized Harmonized Standard programs

Two licensees have been acknowledged by GFSI for their Harmonized Standard audit programs:

GLOBALG.A.P. North America

- GLOBALG.A.P. Harmonized Produce Safety Standard V1.0 (HPSS) successfully obtained Benchmarking status to GFSI in 2016.

- The full benchmarking process includes both an assessment of the program’s governance and operational management (Part II), as well as a comparison of the standard to the relevant scope of the GFSI Benchmarking Requirements (Part III).

- GLOBALG.A.P. accredits certification bodies to offer HPSS audits

- Contact: Rebecca Anderson, Technical Key Account Manager, (805) 710-9788, rebecca.anderson@globalgap.org

USDA Agricultural Marketing Service (AMS)

- USDA AMS Harmonized Good Agricultural Practices Plus (HGAP+) was acknowledged as equivalent to GFSI Technical Equivalence requirements in 2018.

- Technical Equivalence is a category of GFSI benchmarking process dedicated to government-owned standards, acknowledging equivalence of the standard’s content to the relevant scope of the GFSI Benchmarking Requirements (Part III). Technical Equivalence does not include an assessment of the program’s governance and operational management.

- USDA offers both a non-GFSI HGAP audit program, as well as the GFSI technically equivalent HGAP+.

- Contact: Jennifer Dougherty, Audit Program Coordinator, (202) 720-5021, jennifer.dougherty@ams.usda.gov

As a grower interested in being certified:

- United Fresh maintains a current list of audit organizations licensed to use the Harmonized. Producers interested in the Harmonized may reach out to them directly.

As a buyer who would like to know more about the requirements in the standard:

- The Harmonized Field Operations & Harvesting, Post-Harvest Operations, and Combined Standards are freely accessibly on this page, as are various technical and commodity guidance resources, updates on training availability, Frequently Asked Questions.

- All links can be found on this page. Become familiar with the different certificate types offered by our licensees, and specify according to your needs (3rd Party, GFSI, technical equivalence, GFSI recognized)

As an audit organization who would like to become a licensee:

- Contact Dr. Emily Griep to review a licensee contract which lists the requirements to become a Harmonized licensee, including (but not limited to) use of the standard verbatim, auditors trained via the official training materials, and participation on the Calibration Committee.

For any stakeholder interested in becoming involved in future decisions on the scope, revision process, and future direction of the Harmonized Standard:

- Become a member of the Harmonized Technical Working Group (TWG).

- Participation on the TWG is an important opportunity for organizations to have a voice in the future of the Harmonized Standard.

- Expect 1-2 update calls per year, based on need and in-person meetings scheduled during the Harmonized revision period (once every 3 years).

- Contact Dr. Emily Griep to become a member today.

WHAT IS THE HARMONIZED, HARMONIZED TO?

In 2009, United Fresh helped convene a diverse group of stakeholders to review and harmonize existing GAP audit standards, with the goal of developing “One audit by any credible third party, acceptable to all buyers.”

Thirteen commonly accepted fresh produce food safety standards were evaluated by a group of 150 volunteer technical experts in the areas of food safety, growing, and handling practices for a wide variety of commodities and growing regions. The group identified the commonalities and selected the words from each that best suited a common standard, without sacrificing any food safety considerations. The end result was the Produce GAPs Harmonized Standard. Additional background on the Harmonized can be found in this 2013 article by Dr. David Gombas.

WHAT IS IFPA’S ROLE IN THE HARMONIZED?

IFPA (formerly United Fresh) facilitated the original development process by coordinating several working groups, consisting of members and non-members, who worked on various aspects of the effort.

IFPA now serves as the Secretariat for the Harmonized Standard. In this role, we maintain the standard and coordinate the efforts of the Harmonized Technical Working Group and Calibration Committee. IFPA does not conduct audits, issue or manage certificates, set prices, or otherwise influence the audit process. Instead, this is done by audit organizations licensed by IFPA.

WHAT COMMODITIES DOES THE HARMONIZED STANDARD COVER/WHAT IS THE SCOPE OF THE HARMONIZED?

The Harmonized Standard is applicable to all growers and packers of fruits, vegetables, or other edible crops for human consumption who can evaluate the food safety hazards and associated risk of their production system and implement appropriate controls.

If producers do not have control over certain aspects of production and/or cannot adequately evaluate food risks, those operations are not eligible to be audited. Individual licensees reserve the right to determine if certain commodities or operation types are not eligible for certification based on their own criteria.

WILL MY CUSTOMERS ACCEPT AN AUDIT PERFORMED TO THE HARMONIZED STANDARD?

The Harmonized is widely accepted. View a representative list of major buyers that accept the Harmonized. IFPA is always happy to share additional information with buyers who may not understand the scope of the Harmonized, the benchmarking with GFSI, or alignment with the Produce Safety Rule. Not surprisingly, some buyers have additional requirements that can be added as riders or addenda.

HAS THE HARMONIZED BEEN BENCHMARKED TO GFSI?

In 2016, GLOBALG.A.P North America successfully took the Harmonized (referred to as “HPSS”) through the GFSI benchmarking process.

Similarly, in 2018 USDA-AMS’s Harmonized Standard (referred to as “HGAP+”) attained technical equivalency with GFSI, a process similar to benchmarking, reserved for government entities. USDA AMS has an FAQ that explains more about the various audits offered by the agency, and their relationship with GFSI.

While IFPA does not directly participate in the benchmarking process for the Harmonized, we do stay informed of GFSI activities. In May 2020, IFPA (formerly United Fresh) submitted comments for the “Race to the Top” Stakeholder Consultation.

DOES THIS MEAN THAT ANY AUDIT TO THE HARMONIZED STANDARD WILL MEET THE REQUIREMENTS OF CUSTOMERS WHO REQUIRE GFSI?

Not necessarily. Although all licensees use the same technical standard (verbatim), the process and structure around conducting the audit is up to each audit organization and is not under the authority of IFPA. This is part of the benchmarking process and may vary. In addition, there are a few additional topics (e.g., food defense) that GFSI requires be added to the Harmonized, and these topics are handled differently by different audit groups.

HOW IS THE HARMONIZED SCORED?

The Harmonized does not including a scoring system. Each audit organization may select a scoring approach (major/minor, numerical score, pass/fail, etc.).

IF DIFFERENT AUDIT ORGANIZATIONS PERFORM HARMONIZED AUDITS, HOW DOES IT REMAIN ‘HARMONIZED’?

All licensees are required to use the same technical standard verbatim, with no changes in wording permitted. Licensees may include additional items in the audit, provided that those items are clearly marked, but they may not delete audit items.

Licensees are also required to select at least one person within their organization to actively participate on the Calibration Committee, which is tasked with resolving disputes or other questions regarding interpretation of the standard. The Calibration Committee convenes quarterly to discuss these interpretation questions and to otherwise keep the Committee informed on relevant updates regarding the Harmonized Standard.

HOW DOES THE HARMONIZED COMPARE TO THE PRODUCE SAFETY RULE?

They line up well. In July 2016, the Technical Working Group (including FDA representatives) for the Harmonized Standard compared the elements of the standard to the requirements in the Produce Safety Rule, and as applicable, the Preventive Controls for Human Food rule. Changes to the Harmonized were proposed, and the updated standard was open for comment before being finalized in late 2016. USDA’s Ag Marketing Service (AMS) has also worked with FDA to attain recognition that the Harmonized adequately covers the requirements of the Produce Safety Rule. IFPA supports this recognition.

SO, IF I’M CERTIFIED TO THE HARMONIZED DOES THAT MEAN MY FARM WON’T BE INSPECTED BY FDA?

A Harmonized audit is not a substitute for a regulatory inspection. However, FDA has verbally stated that they are considering how certification by USDA AMS (a sister agency) may, along with other factors, reduce the frequency of inspection.

HOW CAN I FIND SOMEONE TO PERFORM AN AUDIT TO THE HARMONIZED?

IFPA maintains a current list of audit organizations that are licensed to use the Harmonized, as shown above. Producers interested in the Harmonized should reach out to them directly. IFPA does not conduct audits. Licensed organizations are free to determine all aspects of the audit process including fees, scoring, etc. Producers should evaluate different audit organizations to determine which is right for them.

HOW ARE AUDITORS TRAINED?

The licensing agreement requires that “all auditors under the Licensee’s control, care, employment, or use shall not perform any audits under the copyright work until having successfully completed training using official training materials as prescribed by the Calibration Committee.”

HOW OR WHERE CAN I FIND HARMONIZED TRAINING AUDITOR OR GROWER COURSES?

In addition to resolving interpretation questions, the Calibration Committee develops official training materials for the Harmonized Standard. IFPA expects to conduct Harmonized Standard training at least once a year. Although the training is designed specifically for auditors, growers are welcome and encouraged to attend, as is anyone with an interest in the Harmonized. After much request, IFPA is considering developing and conducting grower-specific training in the near future.

Licensees may also conduct training, which may or may not be public.

Training workshops will be posted on the IFPA website. Please contact Dr. Emily Griep if you’d like to request training.

I’D LIKE TO AUDIT TO THE HARMONIZED. HOW CAN I DO THAT?

IFPA makes the technical standard freely available and licenses it to several audit organizations. We do not conduct audits. It’s up to the licensees to employ (or contract with) auditors, ensure they are trained, manage certificates etc. We recommend you contact one of the audit companies to understand how you can become an auditor for them. State departments of agriculture also perform a number of GAP audits. You can find a list of licensees on the IFPA website.

WHAT IS THE PROCESS TO UPDATE OR ADJUST THE HARMONIZED STANDARD?

Recommendations and requests for changes to the Harmonized must be submitted to IFPA and then reviewed by Calibration Committee for recommendation to Technical Working Group (TWG). The TWG will then consider these comments/proposals and make actionable updates as necessary. All changes to the Standards will be published as draft on the IFPA website with an open industry comment period. Without objection, the final Harmonized documents will become new versions with proper notification to all parties involved. IFPA will be initiating a new round of updates in 2025 and will seek individuals willing to provide service on the Technical Working Group.

WHAT IS THE PROCESS TO RESOLVE DISPUTES ON INTERPRETATION OF THE STANDARDS?

First, the dispute should be brought to the organization conducting the audit for internal resolution. If the audit organization is unable to come to a resolution, the question may then be brought to the Calibration Committee. The committee will discuss the scenario in question and come to a consensus on how to interpret the standard in that situation.

WHO MAKES UP THE TECHNICAL WORKING GROUP (TWG)?

The Technical Working Group is comprised of over 160 stakeholders, representing, growers, customers, suppliers, government, audit companies, and association staff across various commodity sectors. The TWG includes a broad scope of operation sizes and producing regions from North America. Participation on the TWG is open to anyone interested in participating.

To join the TWG, please contact Tressie Jefferson.

WHO MAKES UP THE CALIBRATION COMMITTEE?

The Calibration Committee is comprised of individuals representing organizations holding a licensing agreement for the Harmonized as well as technical industry experts. The Calibration Committee is responsible for real-time dispute resolution on interpretation questions and scenarios and the development of official auditor training materials, as well as ensuring consistency of the standard.

WHERE CAN I FIND THE STANDARDS?

The Harmonized Standards are freely available on this page above.

WHO CAN I CONTACT FOR MORE INFORMATION?

For any further questions, contact Gretchen Wall, Director of Food Safety and Quality.

Remote Audit Recommendations

While IFPA manages the technical food safety aspects of the Harmonized, the COVID-19 pandemic triggered discussion amongst the licensees and the Calibration Committee about their approaches to conducting hybrid and virtual audits. Their recommendations are summarized here.

Download Remote Audit Recommendations

Harmonized Ag Water Risk Assessment

United Fresh’s Food Safety Council and Harmonized Calibration Committee agreed that the industry would benefit from a document that a grower can use to guide their thought process through the assessment of their agricultural water risk. The following document is a compilation of existing resources and approaches developed by the volunteer workgroup.

- Assessing Risk of Pre-Harvest Agricultural Water

- Example Documentation for Ag Water Risk Assessment

- 3.2.2. Interpretation Summary – Considerations for the postharvest use of surface water

Interpretation Summaries

The following summaries reflect the interpretation of specific scenarios that have been brought to the Harmonized Standard Calibration Committee for guidance and deliberation. These interpretations can be used to better clarify the standard, how it might apply to the auditee, or additional insight for auditors in making these determinations.

Food Safety Plan Templates

These resources, including farm food safety plan templates and record keeping logs, were developed for general use by growers and are not necessarily tied to the requirements in the Harmonized Standard. However, they may be a useful resource for growers seeking to document their food safety programs and procedures.

Audit Organizations Using the Harmonized

These audit organizations are licensed to use the Harmonized Standards for GAP audits. Please click on the company name below for more information. Audit organizations listed are for identification purposes only. The International Fresh Produce Association and the Produce GAPs Harmonization Initiative do not endorse or warrant the services of any particular entity.

Americert International

- Website

- Informational Flyer

- Direct Contact: Lacey Harper, GAP Administrator

Artisan Food Solutions

- Informational Flyer

- Direct Contact: Trish Tripp, CEO

Ceres Certifications, International (CCI)

- Website

- Informational Flyer

- Direct Contact: Kari Neubauer, Lead Program Manager

Food Safety Consulting & Training Solutions, LLC

- Website

- Direct Contact: Sergio Nieto-Montenegro, President

GlobalG.A.P.

- Website

- Informational Flyer

- Direct Contact: Rebecca Anderson, Technical Key Account Manager

Lighthouse Food Safety & Quality

- Website

- Direct Contact: Walt Armijo, President

NSF

- Website

- Informational Flyer

- Direct Contact: Reid Watkins, Technical Scheme Lead

Perry Johnson Registrars Food Safety, Inc.

- Website

- Informational Flyer

- Direct Contact: Lauren Maloney, Food Safety Program Admin Manager

Quality Certification Services (QCS)

- Website

- Direct Contact: Ram Balasubramanian, Chief Operating Officer

Quality Fresh, LLC

- Website

- Direct Contact: Scot Bowman, Owner

SCS Global Services

- Website

- Direct Contact: Kristy-Ann Bura, Client Services Manager, Food Safety

United States Department of Agriculture (USDA, AMS)

- Website

- Informational Flyer

- Direct Contact: Jennifer Dougherty, Team Lead

- General Inquires & USDA Audit Information: SCAudits@usda.gov

Harmonized Expert